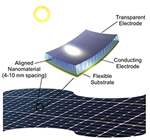

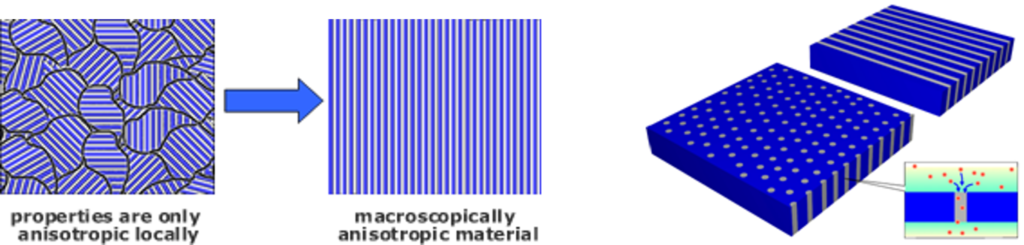

The ability to transform matter that displays novel physics and properties into useful materials and devices is indivisibly linked to the ability to reliably control structure on length scales of interest. This has been well advanced in hard materials where, for example, the growth of meters-long single crystals of silicon via the Czochralski (CZ) process is both indispensable and routine. By contrast, the generation of near single-crystal self-assembled soft matter with arbitrary orientations on length scales beyond 1 mm remains surprisingly challenging. For a broad spectrum of applications ranging from separations membranes to photovoltaics, the need in particular is for control over the out-of-plane ordering of the system, such as in the production of vertically aligned nanostructures. In block copolymer thin films, vertically alignment of domains is sought for optimizing transport properties.

Magnetic Fields

Under appropriate conditions, magnetic fields offer the ability to direct self-assembly of soft mesophases over large length scales in a very straightforward manner. We study the alignment of self-assembled mesophases of liquid crystalline block copolymers (LC BCPs) , surfactants in solution and nanowires in suspension by magnetic fields. In each case, alignment is driven by the presence of a suitably large anisotropy of magnetic susceptibility, even if only diamagnetic in nature. We seek to understand the dependence of alignment on various process and material parameters, as well as the effect of magnetic fields on the phase behavior of these systems. We address the key issue of alignment degeneracy which occurs due to the interaction of uniaxially symmetric structures, such as lamellar sheets and cylindrical microdomains, with a uniaxial magnetic field. We have demonstrated that degeneracy of alignment can be overcome by the use of discrete or continuous rotation of the sample or field, resulting in an effective biaxial field being imposed on the system. Interfacially-driven alignment can exert a non-trivial effect in these systems. We are using grazing incidence x-ray scattering to examine the role of different surfaces on the ability of magnetic fields to overcome substrate-dictated alignment in these systems, i.e. Fréedericksz transitions. A sizeable effort is devoted to in-situ x-ray scattering studies of materials under high magnetic fields (6 Tesla). We have established a unique capability for doing this, with simultaneous small and wide-angle scattering enabled under controlled atmospheres, with concurrent sample rotation. With this capability, we explore alignment pathways and kinetics as a function of process and material parameters (e.g. cooling rate, rotation speed, molecular weight). We also directly examine the role of magnetic fields on the order-disorder transition temperature (ODT) of liquid crystalline block copolymers and surfactant mesophases.

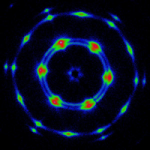

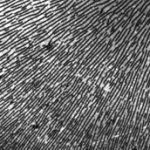

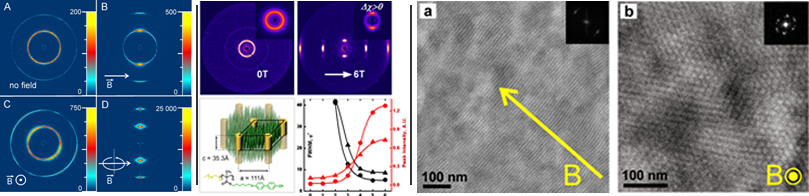

Figure: Left: 2D SAXS of lamellar lyotropic C12E4-water system. Samples were heated to 70 ºC and cooled to 25 ºC at 1 ºC /min. (A) Rotated at 8 RPM, no field. (B) No rotation, 5T field horizontal. (C) 5T field normal to plane of detector. (D) Rotated at 8 RPM about a vertical axis, with horizontal 5T field. The scattering is remarkably sharp. Middle: (a) SAXS at zero field; (b) SAXS and (c) WAXS after alignment at 6T for poly(ethylene oxide-b-methacrylate/cyanobiphenyl) block copolymer. The field is horizontal with respect to the 2D pattern. (d) Variation of the peak intensities of the microdomain scattering (triangles) and LC scattering (circles) as a function of field strength. Black symbols: FWHM from Lorentzian fits. Red symbols: integrated peak intensities. Lines are spline fits. Right: TEM micrographs of a poly(styrene-block-acrylic acid) polymer to which an imidazole terminated biphenyl mesogen has been hydrogen bonded to the acrylic acid block. The supramolecular system forms lamellar or cylinders depending on composition and can be field aligned due to the magnetic anisotropy of the mesogen. The PAA domains appear dark due to OsO4 staining. The lamellar interfaces are aligned perpendicular to the indicated field direction whereas cylinders are aligned along the field. Insets show FFTs of the images, revealing 2-fold and 6-fold symmetries of the morphologies.

Electrospray deposition of block copolymers: Substrate directed assembly

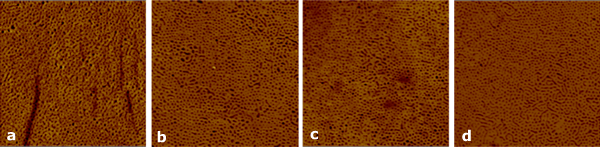

Physical vapor deposition processes enable the production of highly ordered crystalline (inorganic) materials via continuous epitaxial growth under high vacuum. While spin coating is a proven means for producing polymer films with a well-defined thickness, it does not permit the continuously equilibrated growth dynamics of vapor deposition, which may be preferable in some cases. We have proposed electrospray as a novel means for the continuous deposition of block copolymer thin films equilibrated with their substrate. Fine droplets are produced by Coulomb repulsion and evaporate during flight, delivering sub-attoliter quantities of material to the substrate. The deposited material relaxes in the presence of any features present on the substrate, permitting a quasi-epitaxial or templated film growth. We are exploring this process in detail. We seek to understand the role of key process parameters such as substrate temperature, molecular weight and solvent selectivity on the film growth. The fidelity with which the film reproduces the substrate template is a key concern.

Figure: AFM phase images (2 micron view) showing morphology of poly(styrene-block-ethylene oxide) electrosprayed at 2, 4, 8 and 16 ul/min.

Solvent vapor permeation

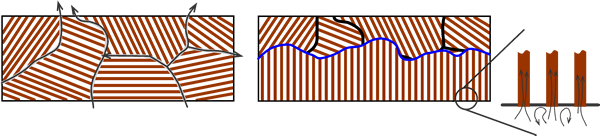

We have recently developed a new approach to aligning block copolymer microstructures vertically in thin films. The technique, solvent vapor permeation, is based on pressure driven transport of a solvent in the vapor phase through a free-standing film, resulting in long range order and alignment of anisotropic nanostructures present in the system. Alignment can be achieved over large areas (> 1 mm-scale) on relatively short timescales of roughly one hour. Our work here is focused on elucidating the mechanism via which solvent vapor permeation aligns such systems. We explore in detail the roles of solvent selectivity, pressure, flow rate and temperature, among others, on the pathways and kinetics of alignment. The goal is to construct a phenomenological understanding of alignment by solvent vapor and to develop robust processes for performing such.

Figure: Alignment of block copolymer microstructures by solvent vapor permeation likely involves differential solvent permeation through the film which may discriminate between grain boundaries and ordered regions (Left), or between the blocks themselves (Right).