Components:

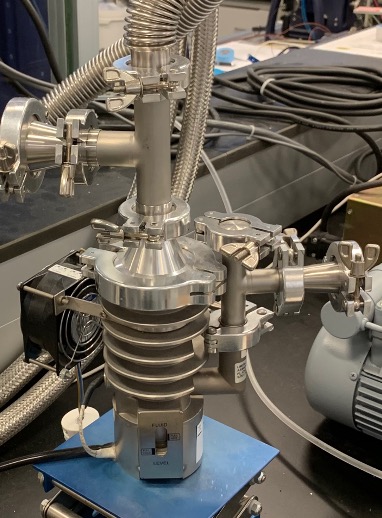

Magnet Chamber (Back)

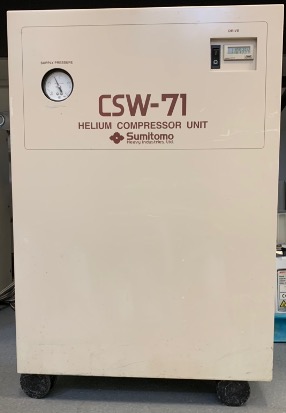

Helium Compressor

Diffuser Pump

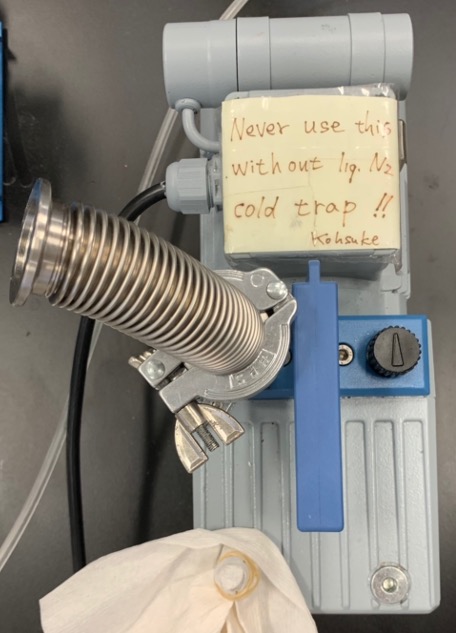

Oil Pump

Pressure Gauge

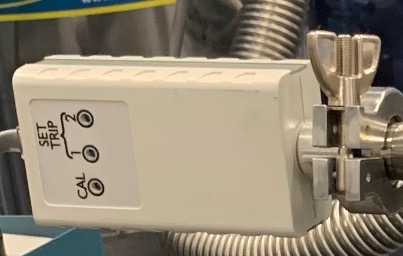

Pressure Sensor

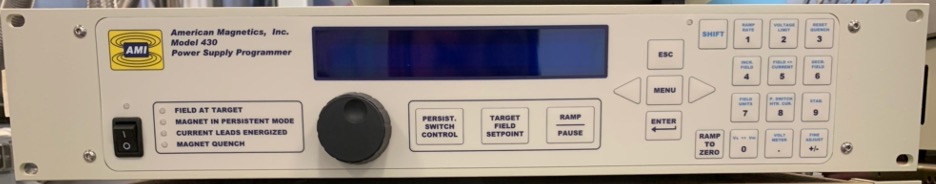

Magnet Controller

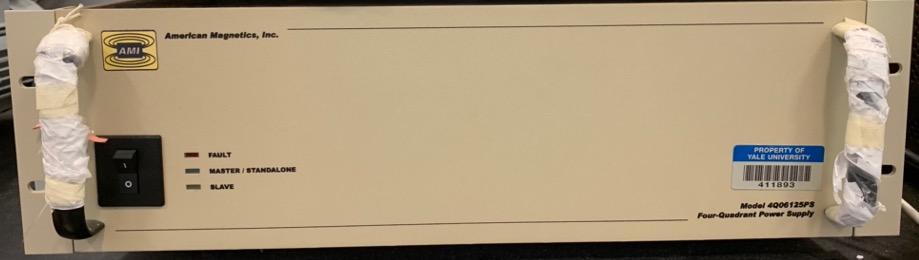

Magnet Power Supply

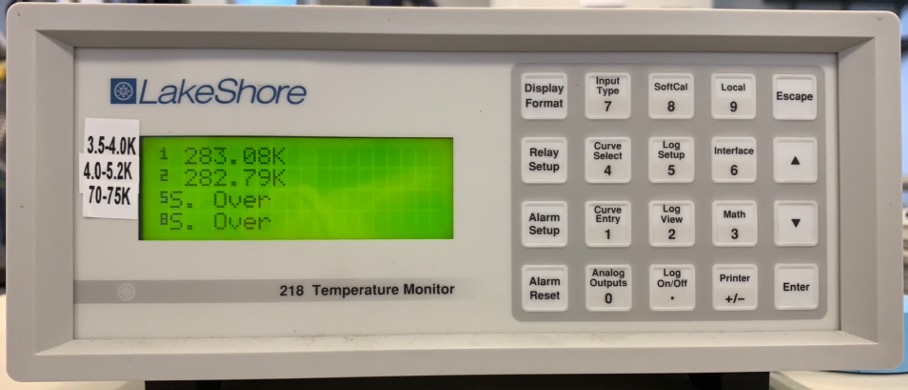

Temperature Monitor

Procedures:

After the magnet quench or power shutdown, the SAXS magnet needs to be restarted. The following procedures help you to restart the magnet properly.

If the magnet is quenched, you should reset the quench and unlock the panel on the magnet controller. Determine the cause and type of quench.

| Compressor | Temperature | Procedure |

| On | Normal | Ramp the magnet |

| Off | High | Turn on the compressor, restore the temperature, ramp the magnet |

| Off | Cannot be restored | see the details below |

| Off | RT | see the details below |

In the case of that the compressor is off and the temperature cannot be restored, you should turn off magnet system before restarting it. Please, turn off the following in order properly:

- Magnet Power Supply

- Magnet Controller

P.S. To turn on the system, first, turn on the controller, then turn on the power supply.

To restart the magnet,

- Start with, or wait for, the room temperature, see from the temperature monitor

- Vacuum the chamber

- Connect the oil pump to diffuser pump; connect the pressure sensor to the diffuser pump; connect the diffuser pump to the magnet chamber.

- Connect the pressure sensor to the pressure gauge and turn on the meter.

- Turn on the pump and wait for the pressure to reach 1×10-2-1×10-1 mbar, see from the pressure gauge connected to the diffuser pump. It usually takes about 20 min.

- Open the chamber valve by the following steps

- Make sure valve is at close state

- Turn the knob clockwise several revolutions

- Pull the knob lever completely to open the valve. In meanwhile, the pressure should change, and increase, on the pressure gauge, which indicates that you open the valve properly. If not please close the valve and try to open it multiple times.

- Wait for the pressure to go down to 1×10-2 mbar overnight.

- Turn on the diffuser pump and the fan connected to it.

- Wait for the pressure to reach 2×10-3-5×10-3 mbar. It usually takes about 15 min.

P.S. If the diffuser pump operates at full hot state for too long, such as more than 15 min, the pressure will increase causing by the oil evaporation. If you observe the increasing pressure, you should immediately turn off the diffuser pump, wait for it to cool down, and restart the diffuser pump to reach desired pressure. - Close the chamber valve by the following steps

- Push the knob lever in completely

- Turn the knob counterclockwise one or two revolutions, no more than three.

P.S. if you turn it counterclockwise too much, the metal block inside of the valve mechanism will fall off from the knob lever. To fix it, you have to uninstall the whole valve from the magnet chamber and reconnect the block to the knob lever. - In meanwhile, the pressure should decrease to 5×10-4 mbar on the pressure gauge, which indicates that you close the valve properly.

- Turn off the diffuser pump and keep the fan and oil pump on until it cools down.

- Turn on the helium compressor

- Manually log the pressure on the compressor, especially in the first 4 hours.

- Manually log the temperature from the temperature monitor. Click Log Setup on the panel to set log preferences. Click Log On/Off to start logging the temperature, and you will see D appears on the monitor.

- Enter the temperature and pressure data to Excel file. The file can be found the SAXS computer with directory C:\Osujilab\Magnet related\magnet_cooldown_log_{date}. Compare the temperature curve to the previous records. The three temperatures on the temperature should matching the target temperature indicating on the monitor.

- If everything is running properly, turn on the magnet system. First turn on the controller, then turn on the power supply.

- Switch the controller from panel control to remote control. (recommended)

- Ramp the magnet to the desired field strength, no more than 58 kG.